Automate Your Way to Success

ROBOMACHINE

ROBOMACHINE include

ROBODRILL (Compact Vertical Machining center),

ROBOSHOT (All Electric Injection Moulding Machine)

and ROBOCUT (CNC Wire EDM).

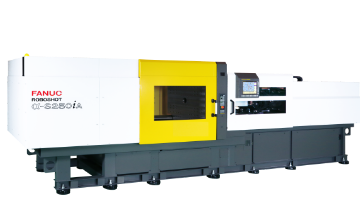

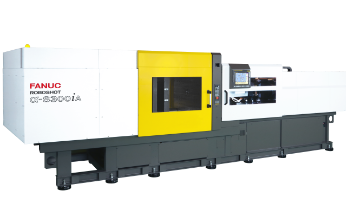

ROBOSHOT

ELECTRIC INJECTION MOULDING MACHINE

Unique Features:

Unbeatable CNC

FANUC Series 31-iB CNC with 21.5” Full HD display delivering High Precision moulding with Superior closed loop control. Ensures process repeatability and consistent high-quality parts.

AI Mould Protection | Ejector Protection

Offering an unrivalled level of protection, ROBOSHOT’s AI Mould Protection function measures pressure on the mould and prevents the clamp from closing should it become obstructed and enhances mould life. AI Ejector safety protects ejector pins, significantly reducing your maintenance costs.

Unrivalled Repeatability

No matter how many parts you produce on ROBOSHOT, it delivers commanded Injection Speed with positioning accuracy along with precise pressure control. This achieves high level of process consistency & part weight consistency.

One Machine for all your injection moulding needs!

- Highly Flexible Injection unit with multiple Screw Size options, Multi-stage Injection Speed & Pressure – Serves range of industries.

- Servo acceleration supports variable injection speeds. Servo deceleration control of holding pressure based on application like Thick parts & Thin parts.

- Roboshot handles a diverse range of sophisticated applications such as Automotive, Medical, Electrical, Packaging, Lens and Metal Injection moulding.

Predictive Maintenance - Backflow Monitor

Unique Feature shows through graph what is happening inside the barrel which allows you to monitor the life cycle of wearable parts such as screw head assembly. This helps operations team to plan parts in advance and avoid machine down time.

Power Regeneration

FANUC Servo Technology is the prime source for Energy Saving through “Power Source Regeneration Function” which demonstrates 16% Power Saving vs Other Electric machines. Our CNC facilitates live monitoring of Regenerated Power

Say Yes to Experience Electric Technology

Please visit any of our 3* Tech-Centres to experience live moulding trials.

* Located at Bangalore, Pune & Manesar