FANUC Academy

Learn from the Best in Business

Learn from the Best in Business

Training Centers

Training programs are conducted across FANUC India’s training centers in Ahmedabad, Bengaluru, Chennai, Coimbatore, Manesar, Pune and Rajkot.

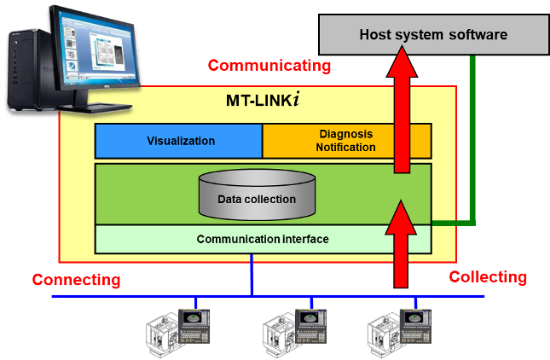

FANUC India’s training centers offer entry-level training in CNC and ROBOT operations and programming, as well as expert courses in FCT (Fine Cut Technology), FST (Fine Surface Technology) and IIoT (Industrial Internet of Things) among others. Certified by one of the largest implementers of IIoT in the country, students are well-equipped to take on the future challenges of industrial automation after completion of these courses.

FANUC India’s training centers offer entry-level training in CNC and ROBOT operations and programming, as well as expert courses in FCT (Fine Cut Technology), FST (Fine Surface Technology) and IIoT (Industrial Internet of Things) among others. Certified by one of the largest implementers of IIoT in the country, students are well-equipped to take on the future challenges of industrial automation after completion of these courses.

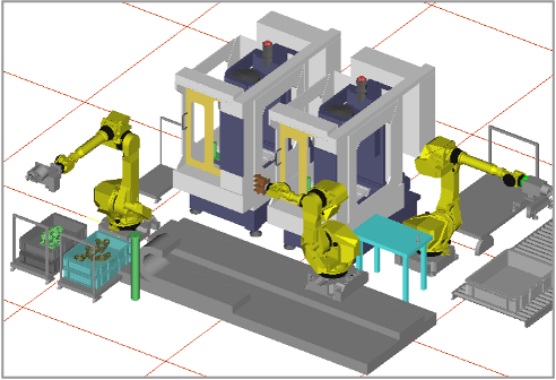

State-of-the-art Facilities

FANUC

Center of Excellence

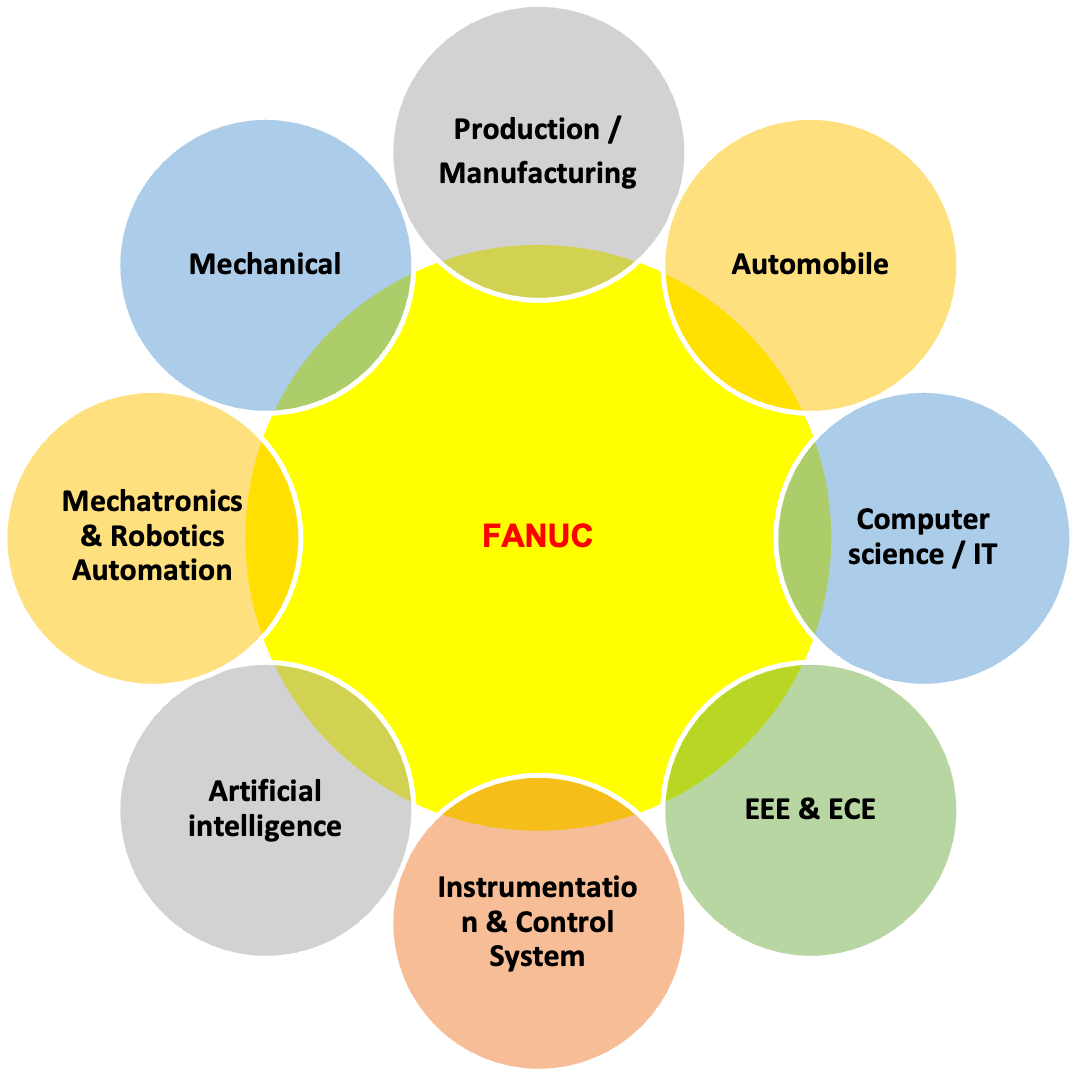

- FANUC India works with ITI, Polytechnics, engineering colleges, universities and Skills Development Training Institutes in establishing Centers of Excellence and conducting Joint Certificate Programs.

- Support in setting up of the Mechatronics Laboratory with Control System, Industrial IoT, Artificial Intelligent Robots and Robomachines which help students to be Industry ready.

Technology Learning

- CNC Operations and Programming

- Servo Sizing and Control Systems

- PLC Programming and HMI Development

- ROBOT Operations and Programming

- Factory Automation and Mechatronics

- Artificial Intelligence and IIoT

- Data Analytics and Machine Learning

Training Calendar

FA TRAINING

CNC Programming-Turning /Milling ,Maintenance of FS0iF/FS31iB Systems ,Troubleshooting ,PMC Interfacing of FS0iF Systems,PMC ladder programming

Jul-Sept 2025

Bangalore/Chennai/Manesar/Pune/Coimbatore

ROBOT TRAINING

Robot Operation & Programming, Maintenance, Programming with 2D Vision Sensor

Jul-Sept 2025

Bangalore/Chennai/Manesar/Pune

INSTITUTIONAL TRAINING

Faculty development program in Robotics-Basic Level , Robot Programming course for students

Jul-Sept 2025

Bangalore