Automate Your Way to Success

ROBOMACHINE

ROBOMACHINE include

ROBODRILL (Compact Vertical Machining center),

ROBOSHOT (All Electric Injection Moulding Machine)

and ROBOCUT (CNC Wire EDM).

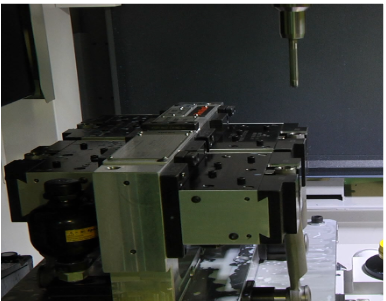

ROBODRILL

High reliability and high performance compact machining center

Unique Features:

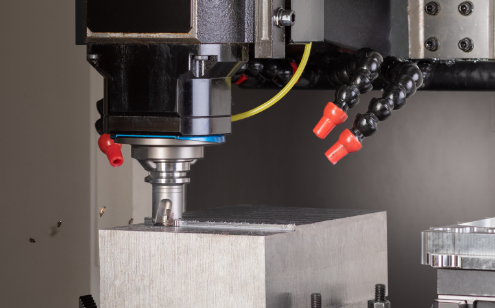

HEAVY DUTY MACHINING SPINDLE

High Torque Spindle offers Cutting torque up to 100Nm, helps higher depth of cuts of milling or U-drilling and tapping in steel and Other special materials.

HIGH SPEED TOOL CHANGE

Standard machine offers tool-to-tool change time of 0.9 seconds and cut-to-cut time of 1.6* seconds helps achieving faster cycle times.

*(2 kg Tool setting)

250mm Tool Length

Robodrill accommodates a maximum of 250 mm length and 80 mm tool diameter. Equally it can accommodate 150 mm tool diameter with special design under FANUC’s guidance.

31iB Plus – Unbeatable CNC

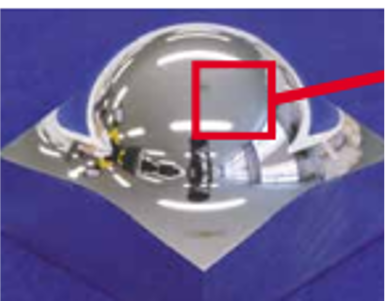

Fine Surface Technology

Smooth tolerance + control achieves fine surface finish by smoothing tool path with short line segments and reduced steps between adjacent paths.

Power Regeneration

Since 1994, ROBODRILL has been equipped to regenerate the energy during motor deceleration. Use of this regenerated power cuts power consumption across the entire factory.

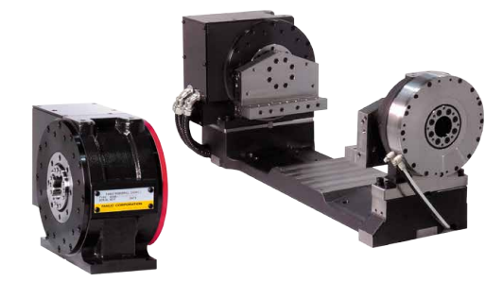

Direct Driven Rotary Table & Cradle Assembly

Add 4th Axis DDRiB & DDR TiB

- DDRi B is a synchronous built-in servo motor and the αiCZ sensor ensures zero backlash, high-speed & high-precision machining.

- DDRTiB is a complete ready-made setup which consists of cast iron cradle plate, tailstock, rotary joint, L plates, etc.

- Thoughtful design ensures full utilization of the X-axis stroke.

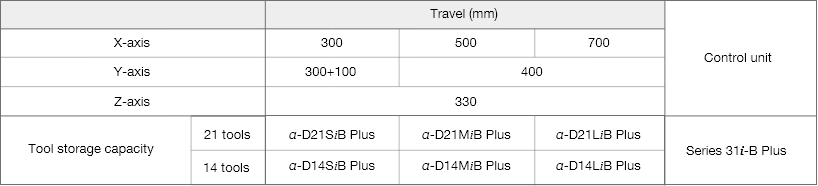

Specifications

Spindle Options