FANUC CNC

For high reliability, precision, speed

and simple operation

Digital Twin For FANUC CNC

Digital Twin

FANUC continues to improve the functions and performance of FA products such as CNCs, Servo motors and Lasers. In addition, FANUC accelerates the efficiency and optimization of machine tool design and work at the machining site via “Digital Twin for CNC” by applying the idea of digital technology (DX).

- Utilize digital technologies such as simulation, based on the feedback from real machine tools by bringing the benefits of CNC technology and digital technology together.

- Improve efficiency and convenience of workflow such as machine tool design, maintenance and machining performance. Support machine tool builders and machine tool users to improve productivity.

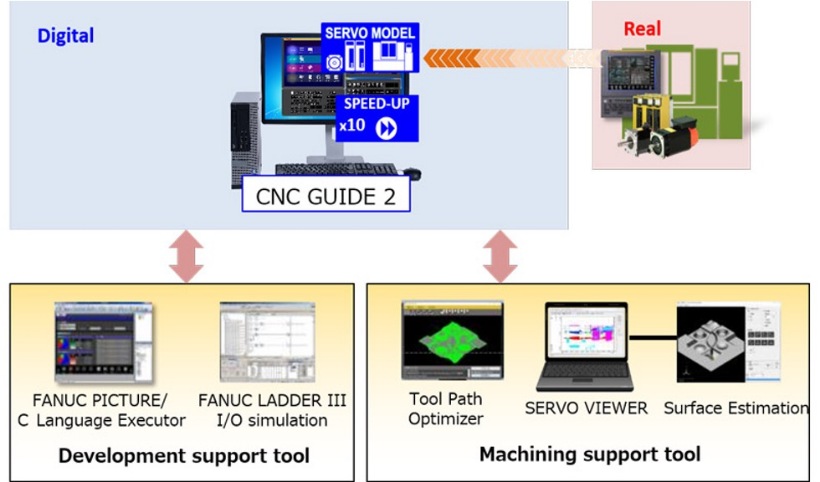

CNC Guide 2

CNC GUIDE 2 is a core technology of Digital Twin for FANUC CNC. It is a software tool that enables verification of CNC functions on PC.

- It faithfully reproduces CNC operations such as acceleration / deceleration and smoothing functions, and it can accurately simulate tool paths and machining times.

- By using Servo Model which reflects machine characteristics, CNC GUIDE 2 can realize more realistic simulation. In addition, it is possible to simulate 10 times faster than actual machining.

- In cooperation with Tool Path Optimizer and Surface Estimation, it is possible to optimize the machining program and simulate the machining surface. In cooperation with FANUC Picture and FANUC LADDER III, it is possible to efficiently develop/ debug custom screens and ladder programs. In addition, it can build a simulation environment easily by connecting to CNC and acquiring parameters, programs, customized data of FANUC Picture, etc. (With CNC GUIDE is also possible to cooperate with these application tools).

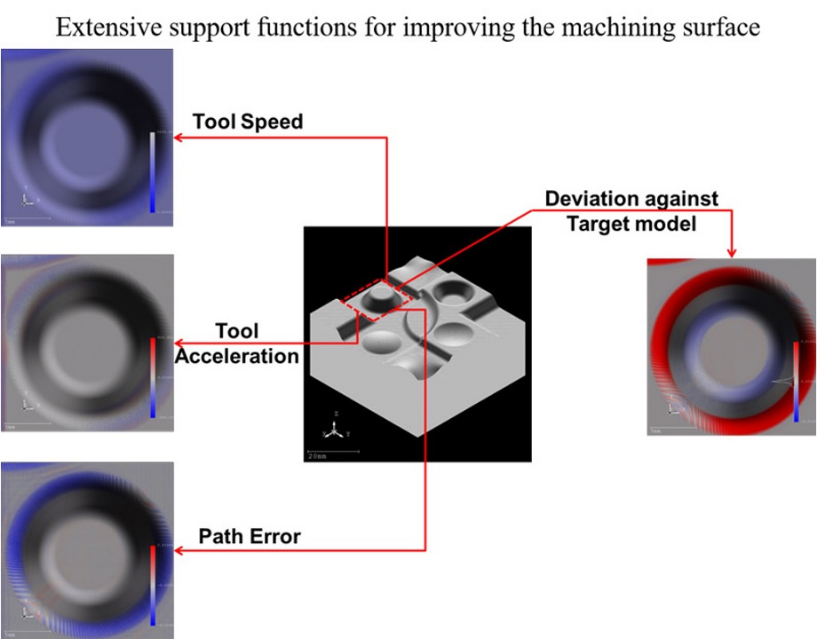

Servo Viewer Surface Estimation

Surface Estimation is a PC software tool that can estimate the machining surface which is close to the actual machining result.

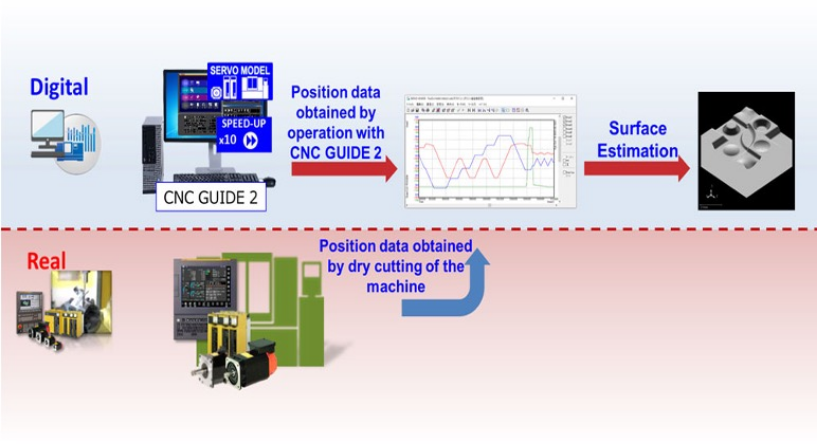

There are two ways to estimate the machining surface.

1. Using the position data of each axis (obtained by running the machining program with CNC GUIDE 2) to estimate machining surface without occupying the machine.

2. Using the position data of each axis (obtained by dry cutting the machining program on the machine) to estimate machining surface without actual machining.

- Support machining surface improvement work by displaying information that affects surface quality onto the machining surface, such as Tool Speed, Tool Acceleration and Path Error.

- The result of surface estimation can be compared with other surface estimation results with different machining conditions, or with the target shape model (CAD model). For example, overcut/uncut finish can be checked by comparing with CAD model.