Automate Your Way to Success

ROBOMACHINE

ROBOMACHINE include

ROBODRILL (Compact Vertical Machining center),

ROBOSHOT (All Electric Injection Moulding Machine)

and ROBOCUT (CNC Wire EDM).

ROBOSHOT – Solutions

Case Study - Automotive

Inception: A Tier 1 (Switches) was facing high Rejections. These were realized post moulding at much later printing stage. We proposed ROBOSHOT as immediate solution.

Response: Customer team visited FANUC Tech centre to witness mould trials. We arranged Test Production over 4 hours and leveraged superior ROBOSHOT features like 1. Pre-Injection function 2. Multistage injection 3. AI pressure profile trace control 4. Precise clamp force control – to ensure Precise control of melt flow from nozzle to each of the 8 cavities in the mould. Customer verified for the quality at their end at post Printing stage.

Result: Rejection rate came down from 16% to 1% with improved Productivity of 11%.

Case Study - FMCG

Inception: A leading supplier for FMCG companies facing aesthetic issues and inconsistent quality besides mould accidents.

Response: Proposed customer for conducting mould trials at mould manufacturer’s premises. Used parallel operations on ROBOSHOT ensuring fast cycle operation and mould safety.

Result: Productivity improved by 21% vs Hydraulic IMM and achieved lowest cost of production per piece.

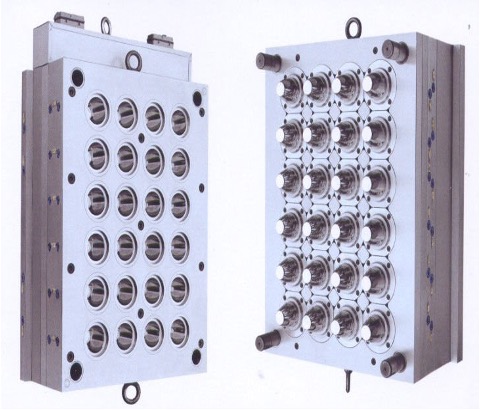

Case Study - Tool Room

Inception: A leading mould manufacturer in India, on its way to expand its footprint in tough European market. Aspires for best machines at his shop floor to help prove its mould’s worth to highly demanding customers in terms of overall superiority, whilst maintaining best possible cycle time & top-notch mould safety levels.

Response: Proposed ROBOSHOT with added value – Unscrewing mechanism using Additional axis servo control, besides other key advantages like Precise process control and High-speed injection thus ensuring perfect component with first time right shot. We also used AI Mould and Ejector protection function and High Response control to achieve optimal results.

Result: This resulted in preventing sink marks and ensured uniform wall thickness. ROBOSHOT is now a preferred choice here.

Case Study - Drip Irrigation

Inception: A Small-Scale company manufacturing drip irrigation parts. Invested in costly multi cavity mould in its quest to achieve higher productivity. Faced repeated problem of mould accidents. Mould repair cost is too high. Looking for an urgent solution for the survival.

Response: We offered solution with ROBOSHOT based on superior AI Mould protection function.

Result: Sensitive AI mould safety resulted in negligible Mould Maintenance Cost – Due to accident-free operation.

Case Study - Food Containers

Inception: While persuading a hydraulic machine user (Food container, MSME) to consider ROBOSHOT realized their pain point around protecting expensive mould – seeking to address repeated accidents during fast mould open/close.

Response: We knew well the customer’s harsh price pressures and cut-throat environment of Thin-wall containers. Arranged trials at our tech-centre.

Result: Achieved stable moulding plus 1. 20% faster cycle time via parallel operation 2. 51% power savings 3. Shot Weight Consistency ± 0.05gms. 4. Eliminated Warpage & Sink marks.

We serve this highly diversified Plastic Industry with our Roboshot and provide each customer with unfailing Lowest Total Cost of Ownership .