Automate Your Way to Success

ROBOMACHINE

ROBOMACHINE include

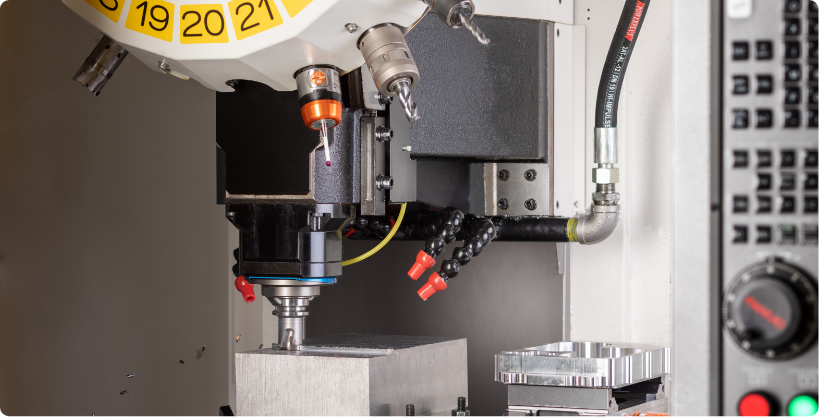

ROBODRILL (Compact Vertical Machining center),

ROBOSHOT (All Electric Injection Moulding Machine)

and ROBOCUT (CNC Wire EDM).

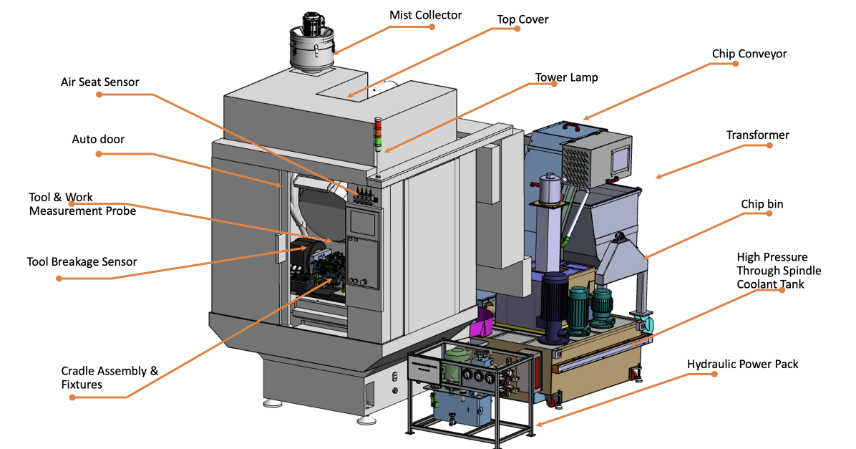

Solutions – ROBODRILL

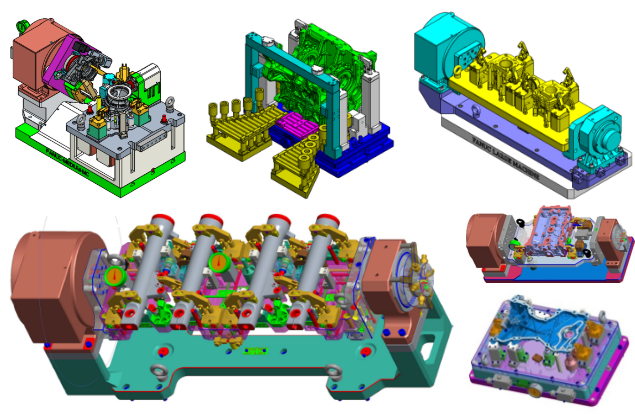

Our engineering depth ensures the best possible solution each time with ROBODRILL, our high-speed compact VMC. We provide the entire breadth of Industrial Engineering – process design, fixture & peripherals, design and building, tool design, project management, assure quality & quantity, installation, prove-out, training and handover.

FIL believes in reducing the number of setups in manufacturing. On an average, we reduce 30% of setups compared to conventional type of machining. To eliminate surprises in your next engineering project, contact us for the best cycle times and industry-best productivity.

ROBODRILL in the Automotive Industry

• Suspension components • Transmission components

Due to its versatility, the FANUC ROBODRILL can be used in many different fields. Because of the stiff machine construction of the ROBODRILL, efficient machining operations like face milling, end milling and drilling are possible. The possibility to make multiple face operations using rotary table makes it the best application for machining automotive parts.

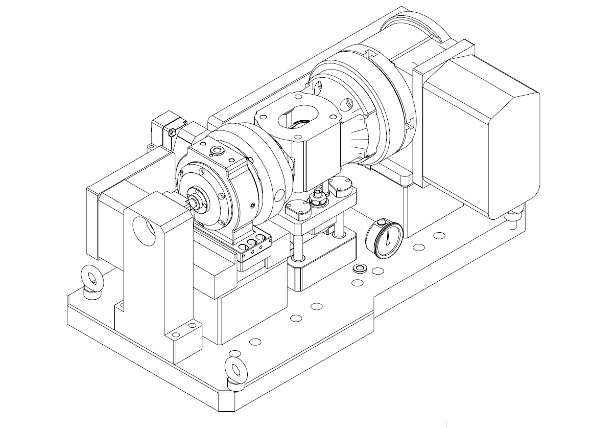

Case Study – Pallet Changer

Enquiry: A Tier-1 manufacturer required VMC with pallet changer. The manufacturer was unwilling to settle for the lucid ROBODRILL + ROBOT combo on their end customer insistence.

Response: Keen to support, we offered ROBODRILL with third-party pallet changer.

Using special material, we designed around the pallet changer’s weight carrying and hydraulic connection limitation.

Result: Manufacturer achieved 25% cycle time savings vs competition. Began receiving enquiries from non-auto segments and these have converted to order.

Case Study – Hand Tools

Enquiry: Our customer required VMC for their end-users hand tool component with stringent accuracy. At the time, the customer machined in 4 setups.

Response: We studied and proposed not just single setup but accommodated 30 variants in in single fixture. We designed a special fixture with movable work-support enabling all sides machining.

Result: Customer achieved promised accuracy, better cycle time.

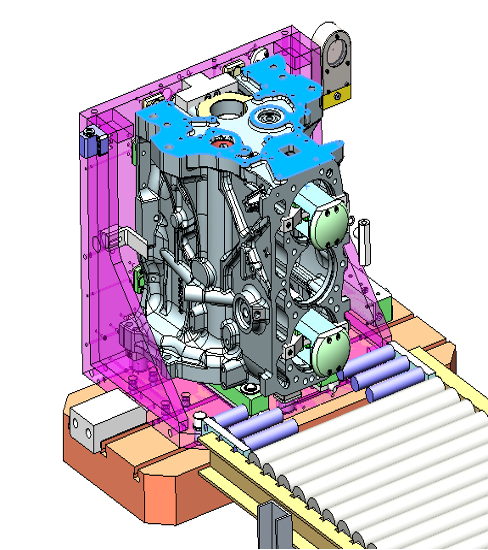

Case Study – Large Component (Agriculture Equipment)

Inception: We persuaded the customer to consider ROBODRILL and step by step convert line of SPM/HMC. Component weight being 128 kg.

Response: We offered Advance series ROBODRILL with 400 mm column riser. We overcame the challenge of heavy component requiring optimal fixture allowing for friendly loading & unloading. ROBODRILL’s 400 kg payload, 4 kg tool weight capacity and 880 mm daylight smoothly exceeded the customer’s expectation.

Result: We continue to net further such opportunities.

Other Segments We Serve

Medical

Aerospace

Agri/Infra Equipment

Electronics

Accessories Solutions

To support a much wider range as well as to optimize costs, we provide specially designed and manufactured local accessories to our customers.

We endeavor to provide reliable and easy to maintain local accessories designed especially for ROBODRILL by our team.